|

Weber tuning for me! This is how I do it.

|

|

Many tuning problems are due to an incorrect ignition timing or spark plugs. Don't forget the ignition leads. Also, always check the carb rubbers and the hoses for the petrol for leaks before adjusting the carbs.

Start by making sure that the CHOKE lever under the dash is pushed in fully. Check that the choke cable is allowing the enrichment levers on the back of the Webers return to their stops. Then loosen the clamps with a 7 mm wrench and push the levers to their stops. Do not forget to tighten the clamp screws.

Check the FUEL HOSES for cracks (especially near the ends) or leaks. Replace them if they look too bad. Empty the water separator and inspect or replace the FILTER. Now, check for FULL THROTTLE OPENING.

Have a helper step on the accelerator

pedal while you watch the throttle shafts rotate to the fully

open position. Gently adjust the linkage, if necessary. Make

sure that the bell crank under the carbs is not sticking on its

shaft.

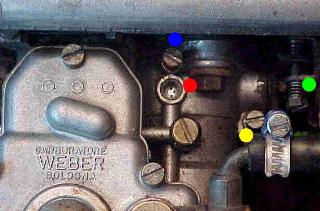

Check and make sure that the throttles are SYNCHRONIZED. Remove the brass plug (above the off-idle holes) of each carburetor section. Shine a flashlight into each of the holes to see that the edge of each throttle plate is aligned with the same hole when the throttle is slightly open. The brass plug is removed on this photo, red dot. There are three holes. Gently adjust the rear carburetor throttle by tampering with the idle adjusting screw, yellow dot. Check that you can see the throttle through one of the holes.

Adjust the spring- loaded screw, green dot, in the linkage between the two Webers until you can see the throttle through the corresponding hole. Use a mirror and a light and shine through the holes by the air cleaner. Then you have the carbs synchronized Now gently adjust the idle screw a few turns. Later, you will have to adjust this screw again to get the proper idling revs. The spring- loaded screw will not need any attention any more.

Make sure that the Idle Stop Screw is NOT against its stop when you are making the adjustment or you will be even more confused.

|